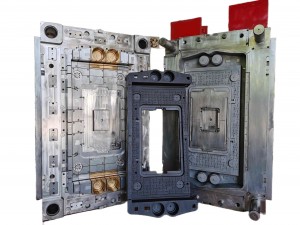

Qhov project no tau muab tso rau Suntime pwm los ntawm kev tsim qauv sai sai rau cov cuab yeej thiab kev txhaj tshuaj molding.Lub tsev nyob saum npoo yog Mould tech kev ntxhib los mos thiab muaj cov ntawv luam tawm hauv nruab nrab vaj tsev.

Cov khoom sib dhos ua siab ntev me me, thiab kev tsim cov cuab yeej yas & molding yog luv heev.Cov khoom siv yog siv rau kev saib xyuas dej hauv tsev thiab kev tiv thaiv.

Rau qhov project no, peb tau muab cov khoom rau Australia, Tebchaws Asmeskas thiab Flextronics Mexico.

| Khoom siv thiab hom | Kev saib xyuas dej hauv tsev thiab kev tiv thaiv | |||||

| Lub npe | Sab saum toj vaj tse thiab hauv qab vaj tsev / Sab saum toj thiab hauv qab Cap / 9V roj teeb BOX & Roj teeb Cap | |||||

| Resin | ABS / TPE | |||||

| No. kab noj hniav | 1 + 1 / 1 + 1 / 1 + 1 | |||||

| Pwm Base | LKM S50C | |||||

| Steel ntawm kab noj hniav & Core | P20 HRC27-33/P20 HRC27-33 | |||||

| Tool hnyav | 4 89kg | |||||

| Tool loj | 443x400x510 | |||||

| Nias Ton | 60T, 200T, 160T | |||||

| Pwm lub neej | 800000 | |||||

| Txhaj tshuaj | Txias khiav pwm | |||||

| Txias qhov system | 30 ℃ | |||||

| Ejection System | Ejector pins | |||||

| Cov ntsiab lus tshwj xeeb | Tag nrho qhov project Cheebtsam, xav tau zoo meej mounting thiab silk printing. | |||||

| Kev nyuaj | Kev sib dhos kam rau ua me me thiab kev tsim khoom siv sijhawm luv luv. | |||||

| Lub sijhawm ua haujlwm | 4.5 lis | |||||

| Pob | Khaws hauv Suntime Hoobkas rau ntau lawm | |||||

| Ntim cov khoom | / | |||||

| Lub shrinkage | 1.005 Nws | |||||

| Nto tiav | MT11020/B-3 | |||||

| Cov ntsiab lus lag luam | FOB Shenzhen | |||||

| Export rau | Mexico / USA | |||||

Rau pwm nyob hauv Suav teb rau kev tsim khoom, peb cov neeg tsim khoom tsim cov cuab yeej kos duab raws li tus qauv tsim khoom hauv Suav.

Thaum lub sijhawm ceev heev, peb ua 3D cuab yeej tsim ncaj qha tom qab DFMs.

Feem ntau ua cov cuab yeej ua tsev neeg pwm los pab cov neeg siv khoom kom txuag tau tus nqi cuab yeej.

Sab nrauv vaj tsev 3D

Sab hauv tsev 3D

3D pwm kev kos duab

Suntime muaj ntau yam kev paub ntawm tag nrho cov cuab yeej tsim thiab molding.

Hauv qab no yog ib qhov project nrog PPSU cov ntaub ntawv.

Cov pwm yog cov pwm kub kub, kub ncav cuag 160 degree, txias los ntawm roj.

Lawv yog cov nplhaib rau cov khoom siv yeeb nkab dej.

Nyob zoo sawv ntxov Selena thiab Gevin, thawj zaug kuv xav hais, ua tsaug ntau rau kev tsim cov qauv thiab cov khoom rau qhov project no.Lawv saib zoo heev.

Kuv kuj xav kom dhau ntawm Alex cov lus hais txog nws zoo siab npaum li cas nrog qhov nrawm nrawm ntawm qhov project thiab cov qauv, thiab ua tsaug rau qhov ua qhov no tshwm sim.

Peb txhua tus ua tsaug thiab txaus siab rau txhua txoj haujlwm ua rau qhov project no.

Thov xa peb cov lus ntawm txoj haujlwm ua tau zoo rau lwm tus ntawm koj pab neeg.

— Edmund.T

Peb muaj 7 lub tshuab txhaj tshuaj los ntawm 90 tuj mus rau 400 tuj.

Yog lawm, peb yog tus tsim pwm zoo heev, tsis yog rau cov pwm yas nkaus xwb tab sis kuj yog cov pwm pwm tuag.Peb muaj kev nplua nuj ntawm kev ua cov khoom tuag casting nrog rau cov txheej txheem molding, deburring, tapping, drilling, tho txawv, CNC machining, hlaws blasting, anodizing, plating / painting thiab hais txog.

Peb muaj cov cuab yeej tshuaj xyuas xws li Hexagon CMM, projector, hardness tester, vernier calipers thiab lwm yam.Kev tshuaj xyuas suav nrog kev tshuaj xyuas cov khoom xa tuaj, Kev tshuaj xyuas Hardness, Electrodes tshuaj xyuas, Steel dimension tshuaj xyuas, Moulding cov ntaub ntawv thiab FAI cov ntaub ntawv, IPQC, OQC cov ntaub ntawv thiab lwm yam,.

Peb lub lag luam tseem ceeb yog rau cov yas txhaj tshuaj molding, tuag cam khwb cia pwm ua, yas txhaj tshuaj molding, tuag casting (Aluminium), precision machining thiab sai prototyping.

Peb kuj muab cov khoom muaj nqis ntxiv nrog rau cov khoom siv silicon, hlau stamping qhov chaw, extrusion qhov chaw thiab cov tshuab stainless hlau thiab lwm yam.

Tom qab ntau lawm, peb yuav siv cov yas ua npuas ncauj los yog lub hnab npuas ua thawj qhov kev tiv thaiv rau qhov chaw.Yuav muaj daim npav rau txhua txheej.7-ply tawv cartons yuav siv tau.Yog tias xa khoom los ntawm huab cua, hiav txwv lossis tsheb ciav hlau, cov thawv yuav raug ntim rau hauv ib lub pallet yas.Rau kev nthuav qhia, qee zaum, yog tias qhov loj thiab hnyav, peb yuav siv lub thawv me me ua ntej thiab muab tso rau hauv lub thawv loj rau kev tiv thaiv zoo dua.

Yog, koj tuaj yeem tuaj xyuas peb txhua lub sijhawm.Koj tuaj yeem ya mus rau Hong Kong tshav dav hlau lossis tshav dav hlau Shen Zhen ncaj qha, peb lub Hoobkas nyob ze lawv.Yog tias koj xav tau kev pab rau booking tsev so nyob ze ntawm peb lub Hoobkas, ua siab zoo qhia rau peb paub, peb yuav zoo siab pab.