Cov no yog 3 cov ntsiab lus rau kev kub siab pwm nrog PPSU cob

Dab tsi yog qhov zoo rau cov khoom siv PPSU?

Lub sij hawm luv luv ntawm qhov kub thiab txias ntawm PPSU yas yog siab li 220 degrees, thiab lub sij hawm ntev kub tuaj yeem ncav cuag 180 degrees, thiab nws tuaj yeem tiv taus cov roj kub ib puag ncig ntawm 170-180 degrees.PPSU qhov chaw muaj qhov ruaj khov zoo, thiab tuaj yeem tiv taus dej kub / tub yees / roj roj.Nrog rau cov cuab yeej zoo no, PPSU tuaj yeem siv los tsim cov khoom lag luam zoo thiab cov khoom lag luam siab.Tam sim no nws dhau los ua thawj cov khoom siv los hloov cov hlau, ceramics thiab tawv polymers.

PPSU cov khoom siv tau nce ntxiv hauv kev npaj thiab rov ua kom sov cov zaub mov kub, tshwj xeeb tshaj yog rau cov khoom siv hluav taws xob siab uas yuav tsum muaj qhov ruaj khov siab thiab cov khoom siv hluav taws xob zoo thiab cov khoom siv hluav taws xob zoo nrog rau cov thermal aging kuj, zoo heev hluav taws kub, thiab zoo tiv thaiv corrosion. thiab hydrolysis.

Nrog rau qhov no, nws dhau los ua cov khoom tseem ceeb hauv ntau yam kev siv hauv kev lag luam xws li aerospace, hluav taws xob thiab hluav taws xob, tsheb thiab tsheb thauj mus los.

Yuav ua li cas tswj qhov kub thiab txias rau PPSU molding?

Raws li nrog rau lwm yam engineering thermoplastics, kev ruaj khov ntawm cov khoom zoo molded yuav tsum muaj kev tswj xyuas qhov kub thiab txias ntawm qhov kub txhaj pwm.Ob leeg dej thiab roj tuaj yeem tswj cov pwm kub ntawm 140 thiab 190 degrees.Yog tias cov cuab yeej tswj qhov kub thiab txias tau tsim tau zoo, dej txog 200 degrees tuaj yeem siv los ua qhov ntsuas kub thiab txias.Kev tswj qhov kub thiab txias hauv hluav taws xob kuj tseem siv tau rau qee kis.Ua ntej txhaj tshuaj molding, PPSU cov ntaub ntawv yuav tsum tau qhuav, peb xav kom qhuav cov khoom nrog temperate ntawm 150-160 degrees rau 3-6 teev.Lub thoob ntawm lub tshuab txhaj tshuaj molding yuav tsum tau ntxuav kom txaus.Thiab qhov kev txhaj tshuaj kub yog pom zoo kom tswj tau ntawm 360-390 degrees.

Yuav ua li cas thiaj ua rau lub siab kub txhaj pwm rau PPSU khoom?

Kev txhaj tshuaj pwm rau PPSU cov khoom yuav tsum muaj peev xwm tiv taus qhov kub thiab txias raws li cov cuab yeej kub molding.Ntxiv nrog rau kev siv cov khoom tsim nyog tsim nyog thiab xaiv cov khoom pwm tsim nyog, cov kav dej kub-resistant thiab siab-resistant hoses yuav tsum tau siv los ua kom zoo tshaj qhov tsim ntawm cov cua txias, cov ntsaws ruaj ruaj, thiab cov khoom sib txuas.

Cov ntsiab lus tsim:

1. Kev xaiv thiab kho cov hlau: a).Cov pwm kub yuav tsum yog nyob ntawm 140 txog 150 degrees, thiab lub neej ntawm pwm yuav tsum tau txiav txim siab hauv kev tsim khoom loj.b).Kev kho cua sov pwm yuav tsum yog HRC60-65 tag nrho.c).Kev kho electroplating tuaj yeem ua rau lub neej ua haujlwm molding.

2. Khiav cov duab: puag ncig los yog trapezoid yog haum.Ib qho dej txias slug kuj yuav tsum tau.

3. Hom rooj vag: Pin point gate, tab gate, disk gate, speak gate, side gate, direct gate and sub gate.

4. Gas Venting: Venting tseem ceeb heev rau PPSU khoom pwm.Venting tsis txaus yuav ua rau hlawv, xim hloov thiab ntxhib nto thiab lwm yam.Lub qhov cua yog ib txwm 0.015 ~ 0.2 hli qhov siab thiab tshaj 2 hli dav.

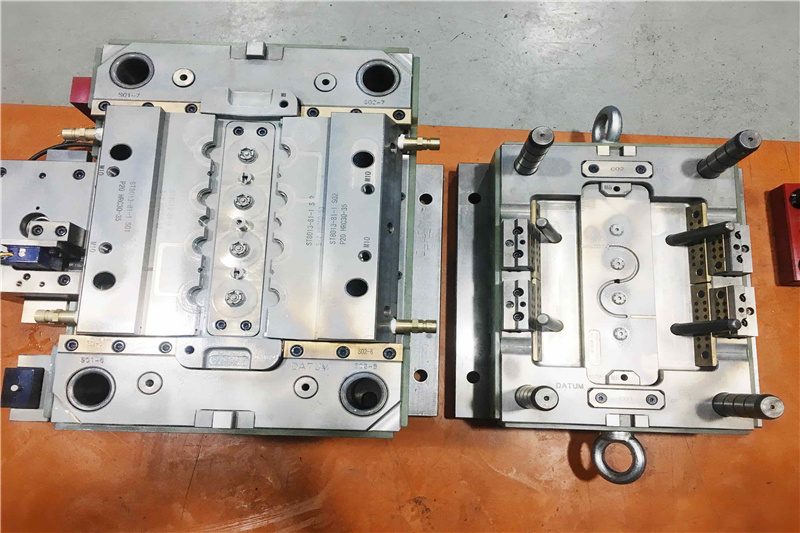

Suntime Precision Mould muaj kev paub dhau los ntawm cov yas txhaj tshuaj pwm ua rau cov pwm kub kub rau cov khoom xws li PPSU thiab PEEK.Cov neeg siv khoom zoo siab heev nrog peb cov khoom zoo thiab lub sijhawm ua haujlwm ceev.Cov duab hauv qab no yog ib qho ntawm cov pwm kub kub uas peb tau ua rau plumping & haum qhov chaw.Nws yog 4 kab noj hniav pib-unscrewing pwm.Yog xav paub ntxiv txog cov pwm no, thov mus saib peb cov ntaub ntawv kawm hauv lub vev xaib:https://www.suntimemould.com/auto-unscrewing-plastic-injection-mould-with-ppsu-material-high-temperature-mold-product/

Post lub sij hawm: Dec-18-2021