| Khoom siv thiab hom | Electronic precision Cheebtsam ua los ntawm ntau kab noj hniav yas txhaj pwm, | |||||

| Lub npe | Mobile connector | |||||

| Resin | Cov khoom siv hmoov metallurgy | |||||

| No. kab noj hniav | 1 * 8 | |||||

| Pwm Base | S50 C | |||||

| Steel ntawm kab noj hniav & Core | S136 HRC 52-54 | |||||

| Tool hnyav | 450 KG | |||||

| Tool loj | 450 X 350 X 370 mm | |||||

| Nias Ton | 90t ua | |||||

| Pwm lub neej | 1000000 txhaj tshuaj | |||||

| Txhaj tshuaj | Kub khiav, 2pcs Mould-master cov lus qhia kub | |||||

| Txias qhov system | Txias los ntawm roj, pwm kub 120 degree | |||||

| Ejection System | Ob kauj ruam ejection | |||||

| Cov ntsiab lus tshwj xeeb | Hmoov metallurgy cov ntaub ntawv, precision txhaj pwm, kub khiav, 8 kab noj hniav pwm, lub sij hawm luv luv | |||||

| Kev nyuaj | High precision kam rau ua, siab kub pwm, luv pwm ua lub sij hawm txhuas thiab luv luv molding lub sij hawm.Cov khoom siv yog Powder metallurgy cov ntaub ntawv uas muaj lub sijhawm txias txias thiab kev thov siab ntawm cov tshuab txhaj tshuaj. | |||||

| Lub sijhawm ua haujlwm | 4 lis | |||||

| Pob | Pwm nyob hauv Suav teb rau cov yas molding ntau lawm | |||||

| Ntim cov khoom | Daim ntawv pov thawj ntawm cov hlau, zaum kawg 2D & 3D cuab yeej tsim, cov ntaub ntawv kub khiav, cov khoom seem thiab electrodes… | |||||

| Lub shrinkage | 1.005 Nws | |||||

| Nto tiav | SPI B-1 | |||||

| Kev txhaj tshuaj molding lub sijhawm | 9 nqi | |||||

| Kev kho thib ob ntawm cov khoom tom qab molding | Kev kho cua sov rau cov khoom molded | |||||

| Export rau | Pwm nyob hauv Suav teb rau cov yas molding ntau lawm | |||||

Cov teeb meem

High precision kam rau ua, siab kub pwm, luv pwm ua lub sij hawm txhuas thiab luv luv molding lub sij hawm.

Cov khoom siv yog Powder metallurgy cov ntaub ntawv uas muaj lub sijhawm txias txias thiab kev thov siab ntawm cov tshuab txhaj tshuaj.

hmoov metallurgy yog dab tsi?

Hmoov metallurgy yog txheej txheem kev tsim khoom uas siv cov kev sib zog sib zog thiab sintering ntawm cov khoom hlau los tsim ntau yam khoom thiab cov khoom.Cov txheej txheem koom nrog kev sib xyaw ua ke ntawm cov hmoov hlau xws li hlau, txhuas, tooj liab, stainless hlau thiab cobalt nrog lubricants thiab khi cov neeg ua haujlwm ua ntej lawv mus rau qib siab.Qhov sib xyaw ua ke yog ces rhuab kom txog thaum cov khoom siv tshuaj fuse ua ke, tsim cov khoom uas muaj zog ntau dua li cov khoom siv los yog cov khoom siv machined.

Vim nws txoj kev ua tau zoo, hmoov hlau metallurgy tau dhau los ua nrov rau kev tsim cov khoom siv hauv tsheb, aerospace thiab cov neeg siv khoom siv hluav taws xob.

Qhov kub kub pwm yog dab tsi?

High-temperature molding yog ib hom kev txhaj tshuaj molding txheej txheem uas siv qhov kub thiab txias siab los tsim cov khoom uas muaj zog thiab ua haujlwm ntev.Cov txheej txheem ua haujlwm los ntawm cua sov cov khoom siv thermoplastic kom txog rau thaum nws yog molten thiab tom qab ntawd txhaj nws mus rau hauv ib lub pwm uas nyob rau hauv qhov chaw nyob rau hauv lub siab.Thaum tshav kub kub los ntawm cov molten resin ua ke nrog lub siab ua rau cov khoom tsim rau hauv cov duab xav tau ua ntej txias.Cov txheej txheem no tso cai rau kev tsim cov txheej txheem nyuaj uas tiv taus qhov kub thiab txias thiab cov tshuaj corrosive, ua rau lawv zoo tagnrho rau kev siv hauv kev lag luam xws li tsheb, aerospace, khoom siv kho mob thiab khoom siv hluav taws xob.

Cov khoom siv yas muaj xws li: PEEK, PPSU, ULTEM® (Polyetherimide, PEI), Celazole®, Vespel®, Torlon® (Polyamide-imide) thiab lwm yam.

Pwm tsim rau kub pwm

Thaum tsim pwm rau high-temperature plastics nws yog ib qho tseem ceeb uas yuav tsum muaj xws li cov cua kub hloov mus raws li zoo raws li siv thermal pins los xyuas kom meej cov yas cools tusyees thaum lub sij hawm txhaj tshuaj molding txheej txheem.

Tsis tas li ntawd, xaiv cov khoom pwm zoo yog qhov tseem ceeb rau kev tsim cov khoom uas tuaj yeem tiv taus qhov kub thiab txias yam tsis muaj warping lossis tawg.

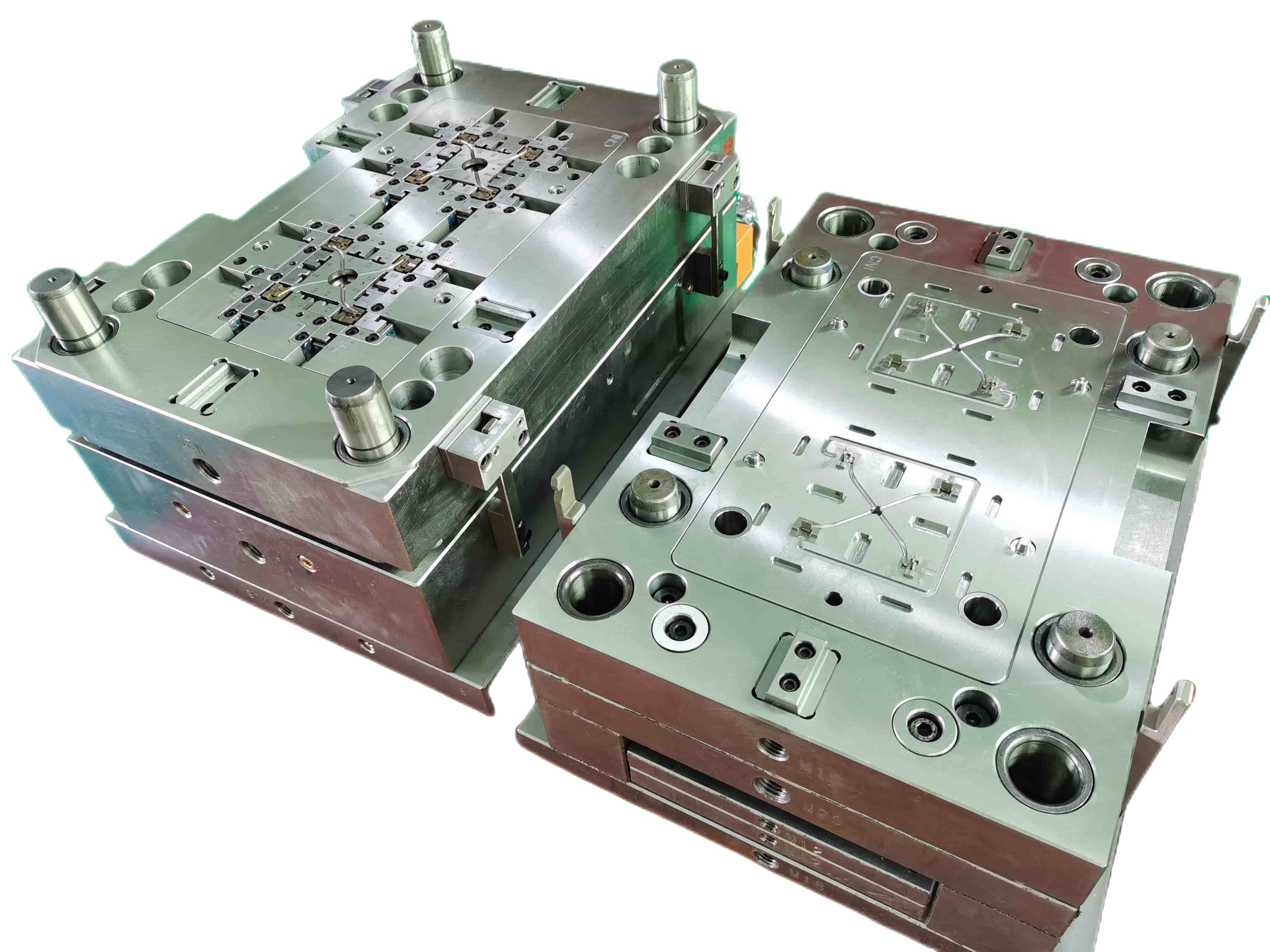

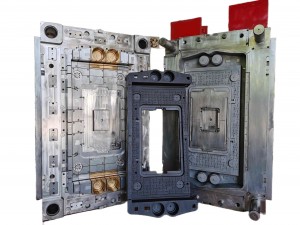

Hauv qhov project no, peb siv cov hlau ntawm S136 nrog HRC 52 ~ 54, qhov ntim ntau lawm, 100000pcs qhov xav tau txhua hnub, yog li peb siv 8 kab noj hniav pwm thiab ua ntau daim ntawv kom tau raws li qhov kev thov kom muaj nuj nqis.Rau qhov txias, nws yog txias los ntawm roj thiab pwm kub ncav cuag 120 degree.Lub sijhawm voj voog yog 9 vib nas this thiab peb siv 2 kauj ruam ejection rau qhov tso tawm.Qhov no yuav raug kho kom sov tom qab molding.

Cov cuab yeej txhaj tshuaj pwm yog 8 kab noj hniav kub txhaj pwm.

Yas yog hmoov metallurgy cov ntaub ntawv thiab cov molded qhov chaw yuav tsum tau kev kho cua sov raws li nws yog lub mobile connector.

Kev txhaj tshuaj molding lub sij hawm luv luv, 9 vib nas this rau ib qho kev txhaj tshuaj.

Peb tau ua ntau cov cuab yeej luam tawm rau cov neeg siv khoom no.Peb cov neeg tsim qauv ua haujlwm tau zoo, rau DFM, nws ua tiav hauv 1 hnub, 2D layout hauv 2 hnub, thiab 3D hauv 3 hnub.

Lub sij hawm tsim cov pwm yog 4 lub lis piam.

Rau pwm tsim, thaum lub sij hawm ceev heev, peb ib txwm ua 3D kos duab ncaj qha tom qab DFM, tab sis tau kawg, nws yuav tsum yog raws li cov neeg siv khoom pom zoo.

2D layout

3D pwm tsim

3D pwm tsim

FAQ

Peb lub lag luam tseem ceeb yog rau cov yas txhaj tshuaj molding, tuag cam khwb cia pwm ua, yas txhaj tshuaj molding, tuag casting (Aluminium), precision machining thiab sai prototyping.Peb kuj muab cov khoom muaj nqis ntxiv nrog rau cov khoom silicon, hlau stamping qhov chaw, extrusion qhov chaw thiab stainle

Tsis yog, peb yog cov pwm tsim thiab yas txhaj tshuaj molding Hoobkas.Peb tuaj yeem muab cov duab tso npe rau kev siv thiab lwm yam ntaub ntawv koj xav tau yog tias xav tau.Lub caij no, koj tuaj yeem tuaj xyuas peb txhua lub sijhawm, txawm tias tsis muaj sijhawm teem sijhawm.

Suntime pab neeg muab kev pabcuam 24/7 ua haujlwm.Rau cov hnub so hauv Suav teb, peb cov muag khoom thiab cov engineers tuaj yeem ua haujlwm ntxiv sijhawm rau koj qhov xwm txheej ceev.Thiab thaum muaj qhov tsim nyog, peb yuav ua qhov zoo tshaj plaws los nug cov neeg ua haujlwm ua haujlwm dhau sijhawm thaum hnub so los ntawm kev ua haujlwm nruab hnub thiab hmo ntuj ua haujlwm kom tau raws li koj cov kev xav tau ceev.

Peb muaj ntau tshaj kaum xyoo exporting kev mus rau lub ntiaj teb no kev ua lag luam, exported yas txhaj pwm, tuag cam khwb cia pwm, tuag casting qhov chaw, yas txhaj molded khoom thiab CNC machining Cheebtsam thiab lwm yam,.

Rau kev tsim pwm, peb muaj CNC, EDM, Sib tsoo tshuab, milling tshuab, drilling tshuab, thiab lwm yam.Rau kev cai yas molding, peb muaj 4 lub tshuab txhaj tshuaj los ntawm 90 tuj mus rau 400 tuj.Rau kev soj ntsuam zoo, peb muaj hexagon CMM, Projector, hardness tester, qhov siab ntsuas, vernier caliper thiab hais txog.