• Qhov kub kub nws pib unscrewing project muaj pwm kub ntawm 160 degree thiab resin kub ntawm 380 degree.

• Qhov no 4 kab noj hniav pwm muaj tag nrho lub sij hawm lub sij hawm ntawm 35 vib nas this nrog du heev unscrewing txav.

• Ib feem yog siab ntev nrog tsawg dua+/- 0.02 hli.

• Cov khoom siv yog siv rau hauv cov khoom siv hauv dej hiav txwv tob.

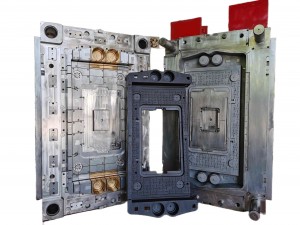

| Khoom siv thiab hom | Cov khoom siv dej nws pib unscrewing 4 kab noj hniav pwm, PPSU khoom, kub pwm | |||||

| Lub npe | MINI PISTON | |||||

| Resin | PPSU | |||||

| No. kab noj hniav | 1 * 4 | |||||

| Pwm Base | LKM S50C | |||||

| Steel ntawm kab noj hniav & Core | H-13 HRC48-50 / H-13 HRC48-50 | |||||

| Tool hnyav | 430 KG | |||||

| Tool loj | 4 93x440 | |||||

| Nias Ton | 120 T | |||||

| Pwm lub neej | 800000 | |||||

| Txhaj tshuaj | Txias khiav pwm | |||||

| Txias qhov system | 160 ℃ | |||||

| Ejection System | unscrewing los ntawm lub cev muaj zog thiab iav log | |||||

| Cov ntsiab lus tshwj xeeb | pwm kub 160 ℃, cov khoom kub 380 ℃ | |||||

| Kev nyuaj | unscrewing du heev, lub sij hawm voj voog 39'S, kam rau ua +/- 0.02mm. | |||||

| Lub sijhawm ua haujlwm | 5 lis | |||||

| Pob | Anti-xeb Ntawv thiab zaj duab xis, me me los tiv thaiv xeb roj thiab plywood box | |||||

| Ntim cov khoom | Daim ntawv pov thawj ntawm cov hlau, zaum kawg 2D & 3D cuab yeej tsim, cov ntaub ntawv kub khiav, cov khoom seem thiab electrodes… | |||||

| Lub shrinkage | 1.007 Nws | |||||

| Nto tiav | B-2 | |||||

| Cov ntsiab lus lag luam | FOB Shenzhen | |||||

| Export rau | Australia | |||||

• Cov cuab yeej txhaj tshuaj pwm yog nws pib-unscrewing los ntawm lub cev muaj zog thiab iav log.

• Muaj ntau lub rwb thaiv tsev nyob rau hauv pwm plaub sab vim pwm kub siab heev.

• Qhov no 4 kab noj hniav pwm muaj tag nrho molding voj voog lub sij hawm 35 vib nas this thiab qhov kam rau ua yog tsawg dua +/- 0.02mm.

Dab tsi yog nws pib unscrewing txhaj tshuaj molding?

Nws pib unscrewing txhaj tshuaj molding yog txheej txheem uas sib txuas cov kev txhaj tshuaj molding ntawm cov ntaub ntawv yas nrog kev tsis siv neeg unscrewing thiab tshem tawm cov ntsia hlau threads (sab nrauv los yog sab hauv los yog ob qho tib si) los ntawm molded qhov chaw.

Cov txheej txheem no yog siv rau kev tsim khoom xws li brackets, knobs, fasteners, caps, li qub thiab lwm yam.

Nws pib-unscrewing txhaj tshuaj pwm muaj ib tug sprue phaj thiab core phaj nrog rau ib tug ntsia hlau xov apparatus uas tso cai rau tsis siv neeg unscrewing tom qab ib feem tau txias.

Cov txheej txheem no tshem tawm qhov xav tau rau kev tshem tawm ntawm cov xov tooj ntawm tes raws li nws tau ua tiav thaum lub qhov tau raug tshem tawm ntawm cov pwm kab noj hniav.

Qhov zoo ntawm nws pib-unscrewing txhaj pwm suav nrog kev txuag nqi vim txo cov nqi zog, txhim kho cov khoom zoo vim tias tsis muaj kev tuav tuav kev koom tes, txhim kho kev nyab xeeb txij li nws tshem tawm tej yam tshwm sim ntawm tib neeg kev ua yuam kev hauv kev tshem cov screws, thiab nce rov ua dua thiab sib xws vim muaj kev sib xws. automated txheej txheem.

Tsis tas li ntawd, cov txheej txheem no tuaj yeem siv los tsim cov khoom nrog cov duab zoo nkauj xws li ntau cov xov sab hauv lossis cov ntsia hlau countersunk yam tsis muaj kev ua haujlwm ntxiv uas xav tau tom qab.

Tsim tawm tswv yim

3D pwm tsim

Pwm tsim rau qhov pib unscrewing pwm

Tsim ib qho pib unscrewing txhaj pwm yuav tsum tau ua tib zoo xav txog cov khoom, cov khoom siv yas, thiab cov cuab yeej loj.Feem ntau cov kev daws teeb meem rau nws pib unscrewing txhaj pwm muaj xws li core insert tsav los ntawm teb, khib, los yog cab.

Thaum tsim ib qho pib unscrewing txhaj pwm, nws yog ib qho tseem ceeb uas yuav tau xav txog cov khoom ntawm cov khoom, xov txoj kab uas hla thiab ntev, phab ntsa thickness thiab xam shrinkage, hom yas thiab fillers siv nyob rau hauv txhaj tshuaj pwm.Tsis tas li ntawd, ib sab pwm yuav tsim nyog los daws cov teeb meem uas tshwm sim thaum qhib thiab kaw cov pwm.Txhawm rau ua kom lub sijhawm voj voog nrawm nrawm thaum tseem ua tiav cov txiaj ntsig zoo, tsis siv neeg unscrewing pwm feem ntau siv.

Muaj 2 hom: phau ntawv unscrewing (tsim los ntawm quab yuam) thiab tsis siv neeg unscrewing.Phau ntawv unscrewing muaj tsawg productivity, tab sis cov pwm qauv yog yooj yim thiab haum rau me me batch ntau lawm;tsis siv neeg unscrewing muaj high efficiency thiab ruaj khov zoo thiab haum rau loj batch ntau lawm.Nyob rau hauv qhov tsis siv neeg unscrewing pwm qauv, cov teeb meem ntawm kev ntseeg siab, stability thiab practicality ntawm cov qauv tsim yuav tsum tau daws.

• Kev tshuaj xyuas cov khoom yas: DFM tsom xam xyuas cov khoom siv rau kev siv thiab nrhiav kev txuag nqi thiab kev daws teeb meem zoo.

• Xaiv qhov kev khiav haujlwm: yog tias qhov ntim ntau lawm yog qhov loj thiab qhov zoo yuav tsum siab, kub khiav (zoo li lub rooj vag valve) yog qhov tsim nyog thiab muaj txiaj ntsig zoo.

• Cua txias:

Txhawm rau txhim kho kev tsim khoom, tiv thaiv qhov deformation ntawm cov khoom yas, thiab tiv thaiv cov kab noj hniav los ntawm thermal expansion ntawm pwm qhov chaw, qhov cua txias ntawm pwm yuav tsum tsim nyog thiab txhim khu kev qha.

• Pwm xaiv cov khoom siv: ib txwm, peb xaiv cov khoom pwm uas muaj siab hnav tsis kam thiab cov ntaub ntawv hardenability.Hauv qhov project no, peb siv H13 steel.

• Pwm tsav ib feem tsim: feem ntau muaj 3 txoj hauv kev los tsim cov tsav tsheb, uas yog Hydraulic lub tog raj kheej + khib, Lub cev muaj zog + saw thiab khib + iav.

Peb cov neeg tsim qauv ua haujlwm tau zoo, rau DFM, nws ua tiav tsis pub dhau 2 hnub, vim tias qhov project yog qhov ceev heev, yog li cov neeg siv khoom yuav tsum tau ua 3D tsim ncaj qha, tsis tas yuav ua 2D layout, yog li 3D tiav hauv 3 hnub.

Peb muaj 6 tus neeg tsim qauv nrog kev paub dhau 8 xyoo hauv tsev.Thiab peb kuj muaj cov neeg tsim qauv uas muaj kev txawj ntse thiab tsuas yog rau pwm & qhov chaw tsim kev lag luam ua thaub qab thaum koj pom zoo cia peb thov kev pab.

FAQ

Rau nws pib-unscrewing txhaj pwm ua

Cov pwm kub yog 160 ~ 180 degree.

Pwm: +_0.01mm,

Plastic Part: +_0.02mm

Machining khoom: +_0.005mm.

Rau cov yas txhaj tshuaj molding, peb siv cov ntaub ntawv yas xws li PPSU, PEEK, ABS, PC, PC + ABS, PMMA, PP, HIPS, PE (HDPE, MDPE, LDPE).PA12, PA66, PA66 + iav fiber ntau, TPE, TPR, TPU, PPSU, LCP, POM, PVDF, PET, PBT ...

Thiab rau kev tuag casting, cov khoom siv txhuas feem ntau yog A380, A356,6061.

DFM: Feem ntau Hauv 2 hnub ua haujlwm.

2D pwm layout: Feem ntau Hauv 3-4 hnub ua haujlwm.

3D pwm kos duab: Feem ntau Hauv 4-5 hnub ua haujlwm.

Peb lub Hoobkas nyob hauv Chang An lub nroog Dong Guan City nyob rau sab qab teb ntawm Tuam Tshoj, uas yog thawj pwm tsim qhov chaw.10 feeb rau Shen Zhen.30 feeb mus rau Shen Zhen tshav dav hlau.

a).Muaj kev paub txog kev muag khoom thiab engineers ua raws li qhov project thiab sib txuas lus ua lus Askiv.

b).24/7 style kev pabcuam.Ib qho rau ib qho kev tswj xyuas qhov project.

c).Tuaj tuaj xyuas txhua lub sijhawm thiab Suntime pab neeg tuaj xyuas cov neeg siv khoom txhua xyoo.

d).qhia txhua lub limtiam txhua hnub Monday.(2 qhia ib lub lim tiam yog xav tau).

e).Txhua emails teb tsis pub dhau 24 teev, koj tuaj yeem hu rau peb txhua lub sijhawm, txawm tias nyob nruab nrab hmo ntuj.