Tej yam koj xav paub txog kev txhaj tshuaj pwm

Kev tsim pwm zoo yog qhov pib tseem ceeb.Nrog koj daim duab kos duab (2d / 3d), peb cov neeg tsim qauv thiab cov kws tsim qauv yuav muaj lub rooj sib tham los tham txog cov qauv, cov teeb meem, cov neeg siv khoom thov thiab muaj lub tswv yim ntawm pwm tsim rau nws.

1. DFM: qhia cov pwm layout tswvyim, cua txias, txhaj tshuaj system, ejection system, phab ntsa thickness, cua ntsawj ntshab lub kaum sab xis, engraving, nto tiav, tsim tsis ua hauj lwm hom thiab cov teebmeem tsom xam thiab lwm yam pwm tso tawm teeb meem.

2. Pwm ntws (muab hauv 1 ~ 3 hnub)

3. Pwm 2D layout tsim (muab hauv 2 ~ 4 hnub)

4. Pwm 3D tsim (software: UG, muab hauv 2 ~ 5 hnub)

Dab tsi yog pwm zoo?Nws yuav tsum muaj cov khoom zoo kom tau raws li qhov kev thov ntau lawm ruaj khov thiab ua haujlwm zoo, thiab tsis tas yuav siv sijhawm ntau dhau & nqi rau kev kho thiab kho.

Suntime muaj 6 tus neeg tsim qauv hauv tag nrho nrog ntau tshaj 5-10 xyoo kev paub, lawv ib txwm them nyiaj tshwj xeeb rau cov neeg siv khoom cov lus qhia thiab cov ntsiab lus los ntawm kev xav txog kev txuag nqi raws li kev ruaj ntseg thiab zoo.Lawv cov kev paub ntau xyoo rau kev xa tawm pwm muab lawv cov kev paub zoo rau cov qauv pwm thoob ntiaj teb thiab cov kev xav tau zoo.

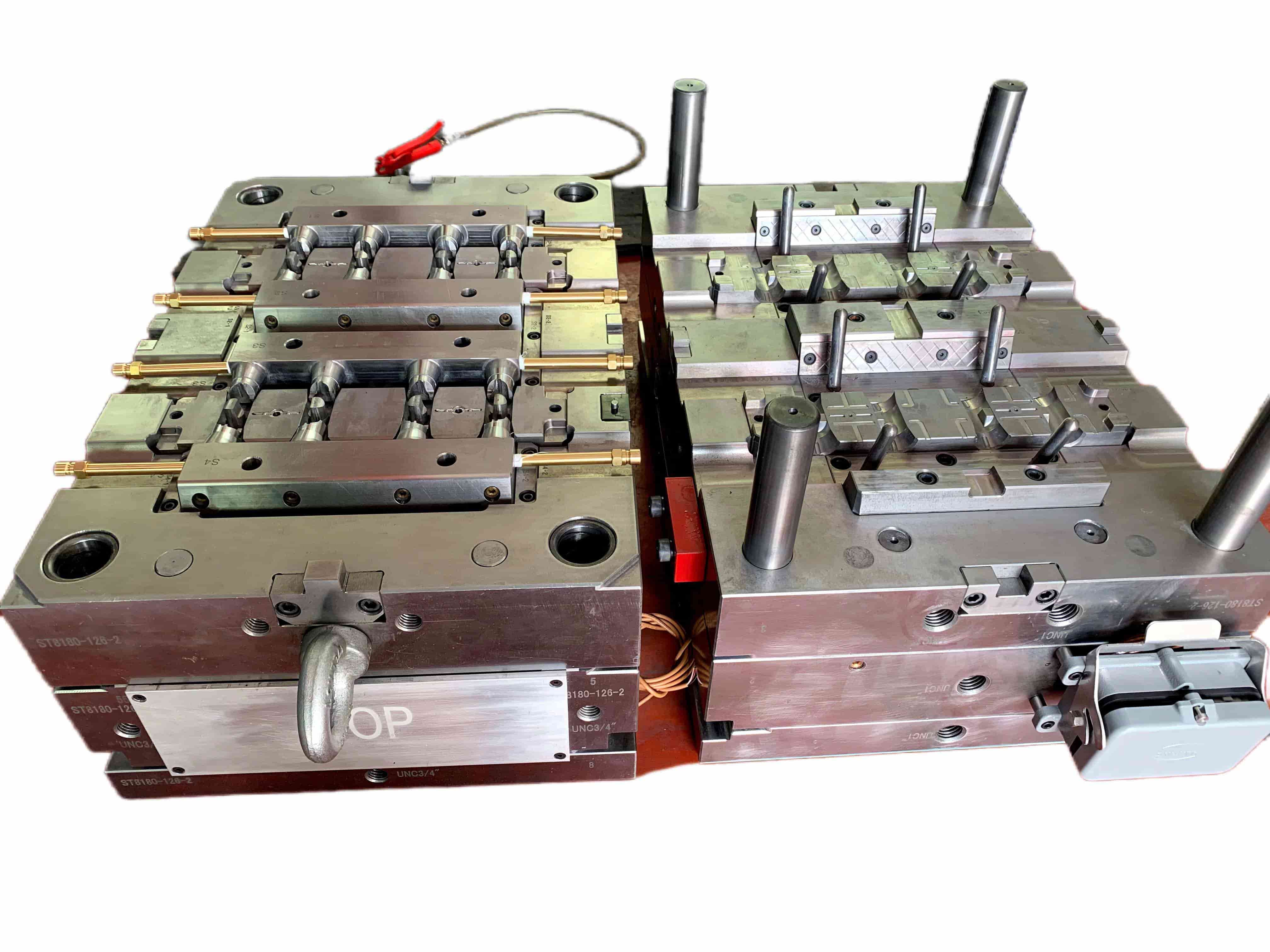

Ib qho pwm tsim siv rau Automotive teeb pom kev zoo npog

Lub tshuab yas txhaj tshuaj pwm tuaj yeem pab cov neeg siv khoom ntau txoj hauv kev.Peb tuaj yeem tsim kev cai yas qhov chaw uas ua tau raws li lawv cov specifications thiab xav tau.Peb tuaj yeem muab kev pabcuam tsim thiab engineering los xyuas kom meej tias cov khoom kawg ua tau raws li cov neeg siv khoom xav tau.Thiab peb muab kev pab cuam tom qab xws li kev saib xyuas thiab kho cov yas txhaj tshuaj pwm uas twb muaj lawm kom lawv khiav zoo tsis muaj teeb meem hauv peb lub Hoobkas lossis hauv cov neeg siv khoom lub tuam txhab.

Raws li kev txhaj tshuaj molding toolmaking, peb tuaj yeem ua rau koj raws li hauv qab no:

1. Kev txhawb nqa ua ntej muag suav nrog tab sis tsis txwv rau kev muab cov lus hais nrawm, tus kws pab tswv yim ntawm cov khoom siv, kev ntsuas DFM thiab lwm yam.

2. Pwm tsim los ntawm DFM, Mould flow, 2D layout tsim thiab 3D pwm tsim.(hauv 2 ~ 4 hnub ua haujlwm)

3. Kev cai pwm tsim rau Yas & Aluminium.

4. Kev pabcuam engineering rau kev ua haujlwm hauv qab no thiab lwm yam haujlwm xws li outsourcing

5. Pwm sim thiab ntim tsawg txhaj molding ntau lawm ua ntej pwm shipping

6. Pwm hloov kho / kho sai

7. Kev thauj khoom thauj los ntawm huab cua, hiav txwv lossis tsheb ciav hlau.

Peb ua dab tsi rau koj qhov kev tswj hwm qhov project (ua haujlwm khiav)?

Kauj ruam 1:Nrog cov neeg siv khoom kos duab kos duab (2D & 3D) thiab cov lus qhia tshwj xeeb, peb tuav lub rooj sib tham nrog cov tsim qauv, engineers thiab tus thawj coj ua haujlwm ua ke kom paub cov ntsiab lus thiab ua cov ntawv sau cia rau cov haujlwm.

Kauj ruam 2:Tom qab cov neeg siv khoom pom zoo rau DFM, lawv pib 2D layout & 3D pwm kos duab & Mould flow tsom nyob rau hauv lub sij hawm luv luv.

Kauj Ruam 3:Thaum lub sij hawm tag nrho cov txheej txheem, txhua lub lim tiam yuav muab qhia txhua hnub Monday kom paub tseeb tias cov neeg muas zaub muaj txhua yam nyob rau hauv kev tswj.

Kauj Ruam 4:Rau kev sim pwm, peb xa daim ntawv tshaj tawm nrog cov duab pwm, cov duab kuaj, cov duab luv luv, daim duab hnyav, cov teeb meem molding thiab peb cov kev daws teeb meem.

Lub caij no, Molding video, soj ntsuam daim ntawv qhia thiab molding parameter yuav muab sai li sai tau tom qab.

Kauj ruam 5:Nrog cov neeg siv khoom pom zoo xa cov qauv, peb xa cov khoom los ntawm kev nthuav qhia hauv Suntime tus account.

Kauj Ruam 6:Pwm kho lossis hloov kho yuav pib ib zaug tom qab kev sib txuas lus nrog cov neeg siv khoom.

Kauj Ruam 7:Pwm tuaj yeem xa nrog cov neeg siv khoom pom zoo.Ntau tshaj 50% pwm yuav tsum tau xa tom qab T1.

Kauj Ruam 8:Shipping pob suav nrog: nco nco nrog qhov kawg 2D & 3D pwm tsim, BOM, cov ntaub ntawv pov thawj, duab thiab qee qhov khoom seem.

Kauj Ruam 9:Ntxuav pwm thiab xyuas ob npaug nrog QC daim ntawv teev npe ua ntej packing.

Kauj ruam 10:Nqus ntim rau kev thauj mus los.

Kauj Ruam 11:Cov ntaub ntawv thiab kev muag khoom txhawb nqa kev cai tshem tawm.

Cov lus hais yuav muab rau hauv 24 teev los ntawm SPM!

Thov xa peb nqe 2D / 3D kos duab rau kev hais lus ceev.

Yog tias tsis muaj cov duab kos, cov duab meej qhia cov qauv thiab qhov ntev, lossis, cov qauv rau peb lub Hoobkas ncaj qha.

Cov ntaub ntawv hom: Dwg, Dxf, Edrw, Kauj Ruam, Igs, X_T

Cov txheej txheem ntawm kev tsim khoom rau kev txhaj tshuaj pwm

Cov txheej txheem ntawm kev ua cov yas txhaj tshuaj pwm tuaj yeem tawg ua cov kauj ruam hauv qab no:

Tsim:DFM tsom xam rau mouldability.Tsim 2D & 3D pwm kos duab.

Machining:Txiav steel thiab siv cov tshuab xws li CNC, EDM, tshuab dhos thiab lwm yam los ua cov duab raws li cov duab kos.

Hardening:Thaum tshav kub kub kho cov hlau kom lawv ncav cuag hardness thiab ruaj khov dua.

Nto:Polishing thiab textures kom tau raws li kev thov kom zoo nkauj.

Assembly & Fitting:Muab tag nrho cov khoom sib xyaw ua ke ntawm qhov kawg pwm thiab ua kom haum.

Kev kuaj pwm:Kuaj tias txhua yam ua haujlwm zoo tom qab sib dhos.

Kev tshuaj xyuas:Nrog molded qhov chaw, ua kev soj ntsuam cov pwm thiab cov qauv los ntawm CMM, projector, thiab lwm yam,.

Kho / hloov kho:Raws li cov qauv, ua kev kho lossis hloov kho uas cov neeg siv khoom xav tau.

Nkoj pwm tom qab cov neeg siv khoom pom zoo.

Yuav ua li cas txuag nqi rau kev txhaj tshuaj pwm?

Yuav ua li cas kom txuag tau tus nqi rau kev ua pwm?Ua ntej, koj yuav tsum paub lub hom phiaj ntawm pwm.Koj yuav siv nws rau dab tsi?Dab tsi yog qhov ntev ntawm qhov khoom koj xav tsim?Qhov ntim txhua xyoo yog dab tsi?Koj xav tau pes tsawg kab noj hniav?Thiab qhov tseeb npaum li cas koj xav tau?Tag nrho cov xwm txheej no yuav cuam tshuam tus nqi ntawm cov pwm.

• Ua kom yooj yim rau kev tsim kom ntau li ntau tau.Qhov ntau txoj kev tsim ib feem yog, cov pwm yuav kim dua.Yog tias koj tuaj yeem ua kom yooj yim rau kev tsim, koj yuav txuag tau nyiaj.

• Siv cov khoom txheem.Tus nqi ntawm kev txhaj tshuaj pwm tuaj yeem raug txo los ntawm kev siv cov ntaub ntawv txheem es tsis txhob siv cov khoom sib txawv.

• Siv cov duab geometry yooj yim.Qhov yooj yim dua qhov geometry, cov pwm yuav kim dua.

• Txo tus naj npawb ntawm cov kab sib faib.Cov kab sib faib yog qhov twg ob feem ntawm cov pwm sib ntsib.Qhov ntau parting kab muaj, cov pwm yuav kim dua.

• Txo tus naj npawb ntawm cov cores thiab inserts.cores thiab inserts yog cov khoom siv los tsim cov kab noj hniav hauv pwm.Qhov ntau cores thiab inserts muaj, cov pwm yuav kim dua.

• Siv cov txheej txheem tsim khoom ib txwm ua.Tus nqi ntawm kev txhaj tshuaj pwm tuaj yeem raug txo los ntawm kev siv cov txheej txheem tsim khoom raws li cov txheej txheem kev cai.

• Siv lub rooj vag yooj yim tsim.Lub rooj vag yog qhov chaw uas cov khoom nkag mus rau hauv cov kab noj hniav ntawm cov pwm thaum lub sij hawm txhaj tshuaj molded manufacturing .Ib qho yooj yim lub rooj vag tsim yuav txo cov khoom pov tseg thiab lub sij hawm voj voog, uas yuav txuag tau nyiaj.

Yog tias koj muaj ib feem ntawm tes xav tau kev txhaj tshuaj pwm, tab sis tsis paub meej tias yuav txuag nqi npaum li cas, tiv tauj peb, peb yuav muab DFM tsom xam dawb thiab qhia rau koj paub peb cov tswv yim.

FAQ

Kev cai yas txhaj tshuaj mould manufacturing

Aluminium tuag casting pwm

Ib txwm yas txhaj pwm

Multi-cavity txhaj mould

Tsev neeg pwm

Kub khiav tshuab pwm

MUD pwm

Tshaj pwm

2k pwm

Nyias phab ntsa pwm

Rapid prototyping pwm

Pwm Flow: Pwm FlowAnalysis

3D Modeling: Unigraphics, Pro/Engineer, Solidworks (cov ntaub ntawv: kauj ruam, Igs, XT, prt, sldprt.)

2D Drawing: Auto-CAD, E-kos duab (cov ntaub ntawv: dwg, dxf, edrw)

Hlau Hom: GROEDITZ / LKM / ASSAB / DAIDO / FINKL ...

Pwm Base: LKM, DME, HASCO, STEIHL....

StandardComponents: DME, HASCO, LKM, Meusburger….

Kub Khiav: Pwm tswv, Mastertip, Masterflow, Husky, Hasco, DME, Yudo, Incoe, Syventive, Pwm tswv ...

Polishing / Texture: SPI, VDI, Mould-Tech, YS....Moulding

PEEK, PPSU, ABS, PC, PC + ABS, PMMA, PP, HIPS, PE (HDPE, MDPE, LDPE).PA12, PA66, PA66 + GF, TPE, TPR, TPU, PPSU, LCP, POM, PVDF, PET, PBT, thiab lwm yam.

A380, AL6061, AL5052, thiab lwm yam.

DFM / Pwm ntws: 1 ~ 3 hnub ua haujlwm

2D tsim: 2 ~ 4 hnub ua haujlwm

3D tsim: 3 ~ 5 hnub ua haujlwm

Cov lus hais hauv 24 teev!

Koj tuaj yeem tiv tauj peb ntawm Emails, hu xov tooj,kev sib tham video,los yog xav tau mus xyuas

Engineers hu ncaj qha ua lus Askiv

Lub sij hawm ua cov pwm tsim (los ntawm kev pom zoo tsim rau T1) yog 3 ~ 8 lub lis piam nyob ntawm pwm complexity thiab qauv.

Tab sis rau tej yaam num ib txwm, nws yog 4 ~ 5 lub lis piam.

Yog, peb yog ISO9001: 2015 ntawv pov thawj

Yog lawm, peb muaj 7 lub tshuab txhaj tshuaj molding tshuab.

Peb cov neeg siv khoom tseem ceeb nyob hauv North America (USA, Canada), Europe (Lub Tebchaws Yelemees, UK, Norway, Denmark, Portugal thiab lwm yam) thiab Australia