Aluminium tuag casting yog txheej txheem uas molten aluminium alloy raug yuam mus rau hauv cov hlau tuag lossis pwm nyob rau hauv siab.Nws feem ntau yog ua haujlwm rau kev tsim khoom loj thiab tuaj yeem tsim cov khoom nrog cov ntsiab lus zoo sib xws nrog rau cov khoom siv nrog nruj heev ntawm tus nqi qis.Cov khoom tsim los ntawm txhuas tuag casting muaj cov cuab yeej zoo heev thiab tiv taus corrosion, kub, thiab hnav.

• Aluminium tuag casting muaj ntau yam txiaj ntsig, qee qhov suav nrog:

• Cov khoom sib sib zog nqus thiab muaj zog uas muaj nqi ntau dua li lwm hom hlau

• Txhim khu kev ua tau zoo vim lub sij hawm luv luv thiab txo cov khib nyiab

• Muaj kev ywj pheej tsim kev ywj pheej vim nws txoj kev ua tau zoo, tso cai rau cov duab nyuaj tsim sai thiab yooj yim

• Kev tiv thaiv corrosion, tshav kub, thiab hnav ntau dua piv rau lwm yam hlau

• Muaj peev xwm ntau lawm, nrog rau feem ntau cov txhuas alloys tuaj yeem tiv taus siab thiab kub

Aluminium tuag casting yog ib qho kev tsim ntau yam tsis txaus ntseeg uas siv los tsim ntau qhov chaw rau ntau yam kev lag luam.Los ntawm cov khoom siv tsheb mus rau kev kho mob cog thiab ntau dua, txhuas tuag casting tuaj yeem siv los tsim yuav luag txhua yam, xws li:

• Automotive kev lag luam:Ntau yam xws li sab hauv trim, kis tau tus mob casings, cav blocks thiab mountings, radiators, thiab them systems.

• Aerospace kev lag luam:Complex Cheebtsam xws li twj, sensors, actuators, xov tooj cua yees thiab antennae.

• Kev lag luam kho mob:Cov khoom tshwj xeeb tshwj xeeb xws li implantable plawv li qub, cov cuab yeej phais, orthotics thiab prosthetics.

• Cov khoom siv hauv tsev:Hinges thiab latches rau cov tub yees thiab tshuab ntxhua khaub ncaws nrog rau lwm cov khoom me me uas yuav tsum tau ua kom paub meej txog kev ua haujlwm.

• lwm yam,.

Xaiv qhov zoo aluminium alloy rau koj qhov project tuag casting yog qhov tseem ceeb los xyuas kom meej tias koj cov khoom tiav raws li tag nrho koj cov kev qhia tshwj xeeb.Nov yog qee cov lus qhia txog kev xaiv cov hlau zoo:

• Xav txog qhov yuav tsum tau muaj zog thiab kav ntev ntawm koj qhov chaw.Cov alloys sib txawv muaj ntau theem ntawm lub zog thiab hnav tsis kam, yog li nws yog ib qho tseem ceeb uas yuav tau xaiv ib qho alloy uas yuav ua tau raws li qhov xav tau ntawm koj daim ntawv thov.

• Ntsuas qhov yuav tsum tau muaj kev tiv thaiv corrosion.Aluminium alloys tuaj yeem kho thiab anodized los muab kev tiv thaiv ntxiv tiv thaiv corrosion, yog li nco ntsoov xyuas seb qhov chaw twg koj qhov chaw yuav tsum tau nyiaj.

• Xav txog cov nqi tsim khoom thiab lub sijhawm xa khoom.Nyob ntawm qhov nyuaj ntawm ib feem, cov alloys sib txawv yuav xav tau ntau txoj kev tsim khoom lossis kev nqis peev, yog li nws yog ib qho tseem ceeb uas yuav tsum ntsuas cov yam ntxwv no thaum xaiv cov hlau rau koj qhov project.

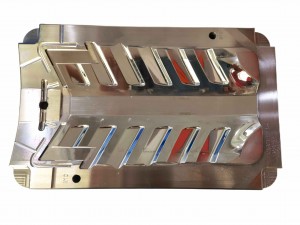

Tooling thiab machining yuav tsum tau rau txhuas tuag casting sib txawv nyob ntawm seb cov alloy siv, complexity ntawm ib feem, thiab lwm yam.Feem ntau, nws yog ib qho tseem ceeb uas yuav tau xav txog cov hauv qab no thaum xaiv hom cuab yeej:

• Kev xaiv cov cuab yeej siv yuav tsum yog raws li cov alloy uas tau siv thiab qhov kub thiab txias yuav tsum tau ua kom tau txais txiaj ntsig zoo.Peb nquag siv H13, SKD61, 8407, 8418, 8433 thiab W360 rau cov cuab yeej tuag.

• Yuav tsum tau saib xyuas kom ntseeg tau tias muaj lub kaum sab xis txaus kom cov khoom txav tau yooj yim txav ntawm qhov tuag thaum tshem tawm.Kev tshuaj xyuas DFM tiav yuav tsum tau ua ua ntej tsim pwm.

• Thib ob machining yuav tsum tau tom qab casting thiaj li ua tau tej yam duab los yog cov ntsiab lus, nws muaj xws li CNC machining, drilling, tapping thiab lwm yam.

• Nto Finishing xaiv xws li xuab zeb-blasting los yog vibratory polishing, anodizing, plating los yog painting tej zaum yuav tsim nyog nyob ntawm seb koj xav tau kev pab.

CNC Machining rau Tuag Casted Parts

Kev daws teeb meem tshwm sim hauv txhuas tuag castings tuaj yeem siv sijhawm ntev thiab raug nqi, tab sis nws yog ib qho tseem ceeb los xyuas kom meej qhov zoo ntawm koj cov khoom.Nov yog qee cov lus qhia txog kev daws teeb meem ntau yam nrog txhuas tuag castings:

• Porosity:Tshawb xyuas koj qhov rau txhua qhov pinholes lossis lwm qhov chaw uas tuaj yeem ua rau porosity.Yog tias koj pom ib qho, nco ntsoov xyuas cov pwm kub, txhaj tshuaj thiab lwm yam uas yuav cuam tshuam rau qhov txhaws ntawm daim.

• Distortion:Yog tias koj pom qhov txawv txav ntawm qhov chaw tom qab lawv tau muab tshem tawm ntawm qhov tuag, xyuas seb puas tsim pwm lossis lub sijhawm txias yuav ua rau qhov teeb meem no.Tej zaum koj yuav tau kho cov teeb tsa no rau kev tsim khoom yav tom ntej txhawm rau txhawm rau txo qis kev cuam tshuam.

• Nto teeb meem:Yog tias koj ntsib qhov teeb meem ntawm qhov chaw xws li splay marks lossis fins, xyuas seb puas muaj qhov tsis sib haum ntawm kev txhaj tshuaj nrawm thiab yaj ntws, vim qhov no feem ntau tuaj yeem ua rau cov teeb meem no.Nws kuj tseem yuav tsim nyog los kho qhov ntsuas qhov ntsuas xws li qhov kub thiab txias kom txo tau qhov tsis zoo ntawm qhov chaw.

Thaum ib qhov project tshiab pib, cov khoom siv prototyping sai yog xav tau rau cov kev sim.Muaj ntau txoj hauv kev los ua cov qauv xws li CNC machining, Nqus casting, 3D printing thiab Rapid prototype tooling.

• CNC machining tuaj yeem ua cov hlau thiab yas nrog txhua qhov ntau.

• Nqus Casting yog rau 5-100 unit yas qhov chaw los ntawm kev siv silicon pwm

• 3D Printing yog luam tawm ABS, PA lossis hlau qhov chaw.Rau cov yas, 3D luam ntawv qhov chaw tsis tuaj yeem sawv kub.

• Cov cuab yeej nrawm nrawm yog cov pwm mos ua los ntawm cov hlau mos xws li S50C lossis Aluminium.Qhov kev daws teeb meem no tuaj yeem tsim ntau qhov chaw ntau dua li lub tshuab nqus tsev casting.Lub sij hawm txhuas yog luv dua li cov cuab yeej tsim khoom thiab tus nqi qis dua.

Cov ntaub ntawv peb tau siv: Cov yas zoo li PC, PMMA, POM, PP thiab lwm yam,.Hlau xws li hlau, txhuas, tooj dag, tooj liab thiab lwm yam.

Yuav ua li cas ua ib qho silicon

Txhawm rau tsim ib feem ntawm silicone, koj yuav tsum tau siv cov txheej txheem ntawm kev txhaj tshuaj molding.Qhov no suav nrog melting yas nyob rau hauv ib lub tshuab txhaj tshuaj thiab txhaj rau hauv lub kaw kab noj hniav, qhov twg nws txias thiab hardens kom coj cov yam xav tau.

Lwm cov txheej txheem koj siv tau xws li xovxwm molding, nqus casting, lossis 3D luam ntawv.Txhua txoj kev muaj qhov zoo thiab qhov tsis zoo nyob ntawm seb hom twg koj tab tom sim tsim.

Nrog rau txhua txoj hauv kev, tau txais qhov kub thiab qhov siab yog qhov tseem ceeb rau kev ua tiav qhov tseeb qhov ntev thiab cov khoom tsim nyog.

Cov khoom siv ntawm cov khoom siv silicon

Muaj ntau qhov kev lag luam tuaj yeem siv silicon mos qhov chaw xws li Automotive, Kev Kho Mob, Hluav Taws Xob, khoom siv hauv tsev, chav ua noj, thiab ntau lwm yam.Rau qhov chaw, feem ntau koj tuaj yeem pom cov no xws li Gaskets, Seals, O-rings, Air filters, Hoses, Lighting Cheebtsam, Cellphone case, Keyboard cover, wires and cables insulation and many Medical devices.

Hlau stamping qhov chaw yog cov khoom siv hlau tsim los ntawm cov txheej txheem hlau stamping, cov txheej txheem tsim khoom uas muaj kev xuas nrig ntaus, txiav, lossis ua cov ntawv hlau rau hauv cov duab uas xav tau.

Hlau stamping yog siv los tsim qhov chaw rau ntau yam kev lag luam xws li tsheb thiab aerospace industries.

Nws kuj tseem siv tau los tsim cov duab kev cai thiab sib txawv.Cov txiaj ntsig ntawm kev siv hlau stamping suav nrog cov nqi-zoo, tsim kev nyuaj thiab yoog raws.

SPM tau pab cov neeg siv khoom hauv ntau cov khoom siv hlau stamping rau lawv qhov project turnkey, peb cov kev pabcuam engineering zoo tuaj yeem txuag tau ntau ntawm lawv cov nqi thiab sijhawm.

Jigs thiab fixtures yog cov cuab yeej siv los pab hauv kev tsim khoom ntawm ntau yam thiab cov khoom.

Lub jig yog ib qho cuab yeej tshwj xeeb uas pab coj, tuav, los yog muab lub workpiece nyob rau hauv qhov chaw thaum lub sij hawm sib txawv machining, xws li drilling, milling, thiab shaping.

Fixtures yog cov khoom siv uas txuas nrog lub tshuab lossis lub chaw ua haujlwm thiab pab nrhiav thiab ruaj ntseg cov khoom thaum lawv tab tom ua haujlwm.

Lawv tuaj yeem ua kev cai tsim los ua kom haum rau ntau yam haujlwm los xyuas kom meej thiab ua haujlwm tau zoo.Ob lub jigs thiab fixtures tuaj yeem ua los ntawm cov hlau xws li hlau lossis txhuas thiab yog qhov tseem ceeb rau kev tsim cov khoom raug nrog kev siv zog tsawg.

SPM ua jigs thiab fixtures rau peb tus kheej txhaj tshuaj molding ntau lawm thiab kuj muab kev pab cuam ntawm ua rau cov neeg muas zaub.

Yog tias koj xav tau qhov no, thov hu rau txhua lub sijhawm.

Tau txais ib qho quote tam sim no!

-

Txhaj ntau kab noj hniav pwm rau lub kaus mom ntawm packa ...

-

Yas tooling tsev neeg pwm automotive tail lig ...

-

CNC milling thiab tig machining cov neeg muag khoom

-

Yas Txhaj Mould Chaw tsim tshuaj paus, tuag Castin ...

-

Kev cai yas txhaj tshuaj molding kev pabcuam

-

Precision yas txhaj mould rau cov neeg siv khoom ...